Unleash the beauty of infinite possibilities with 3D printing in jewellery design.

3D printing in the jewellery industry is revolutionizing the way jewellery is designed and produced. By using 3D printing technology, jewellery designers and manufacturers can create complex and intricate designs with ease, bringing their creative visions to life. 3D printing also allows for greater customization and personalization of jewellery pieces. Additionally, it can reduce production costs and lead time, allowing for more efficient and cost-effective production. This technology also enables more sustainable practices by reducing waste and the need for certain types of mining. Overall, 3D printing in the jewellery industry is opening up new possibilities for design and production, making it an exciting and innovative field to be a part of.

5 Best Advantages Of Using 3D Printing In Jewellery Industry

Jewelry 3D printing has numerous advantages over traditional jewelry manufacturing techniques. One of the main benefits is the ability to create highly detailed and complex designs that would be difficult or impossible to produce using traditional methods. This allows for a greater level of creativity and artistic expression in the design process. Additionally, jewelry 3D printing is much faster and more efficient than traditional methods, resulting in lower costs and faster production times. Another advantage is the ability to easily make small changes or adjustments to designs without having to start from scratch. This can save both time and money in the design process. Additionally, jewelry 3D printing allows for a greater level of customization, as each piece can be tailored to the specific needs and preferences of the customer. Overall, jewelry 3D printing is a revolutionary technology that offers many benefits to both designers and customers.

1. Complex and intricate designs can be easily created with 3D printing technology

2. Greater customization and personalization of jewellery pieces is possible.

3.Enables the use of new materials and techniques.

4.Can increase the precision and accuracy of designs.

5.Can create a new level of innovation and creativity in the jewellery industry.

Steps to create a jewelry using 3D printing technology

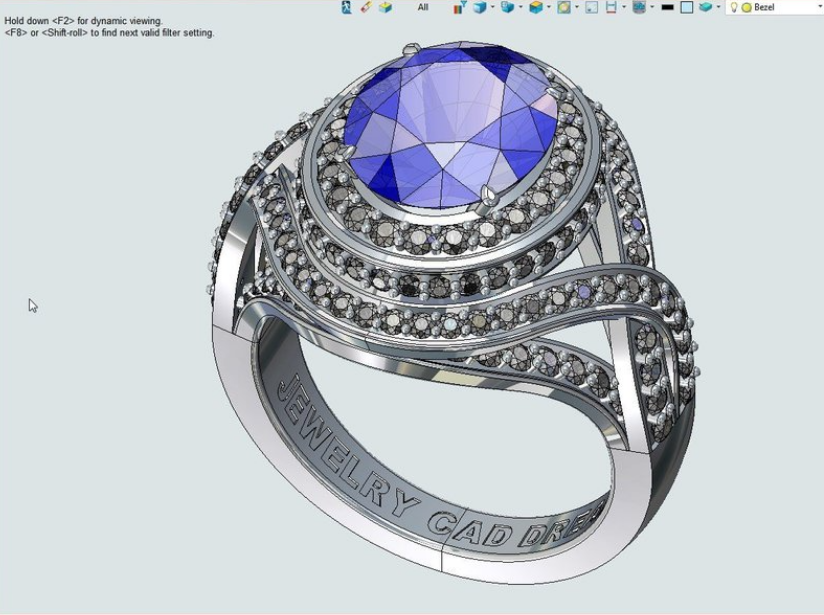

Step 1: Designing the Jewelry

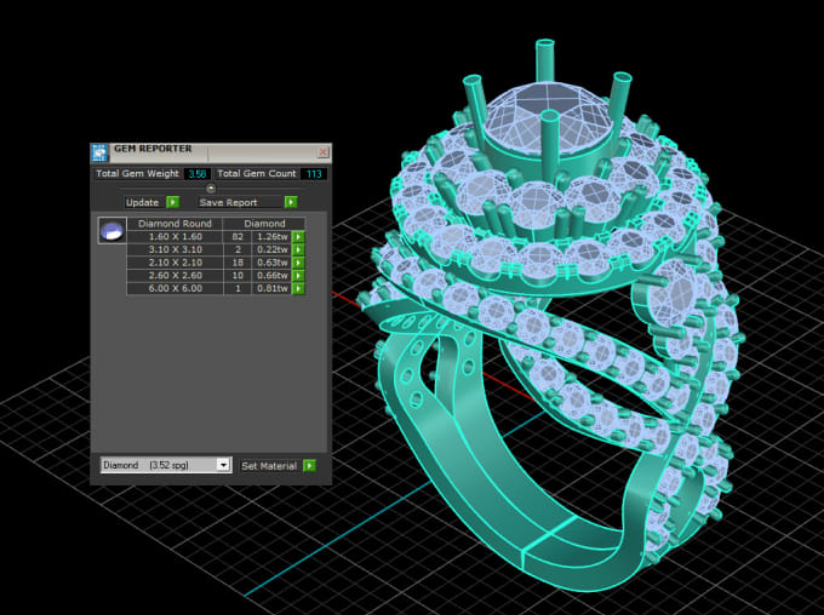

The first step in creating jewelry using 3D printing technology is to design the piece using computer-aided design (CAD) software. This allows for the creation of highly detailed and precise designs that would be difficult or impossible to produce using traditional methods. Many jewelry designers use software such as Rhino, ZBrush, or Autodesk Fusion 360 to create their designs. These programs provide a wide range of tools and features that allow designers to create detailed and complex designs. Additionally, many of these programs have built-in tutorials and guides that can help designers learn how to use the software and create their designs.

Step 2: Preparing the Model

Once the design is complete, the model needs to be prepared for printing. This includes checking for any errors or inconsistencies in the design and making any necessary adjustments. For example, designers may need to adjust the thickness of certain parts of the design or add additional supports to ensure that the piece will print properly. Additionally, designers may need to scale the design to the appropriate size and add any additional details or embellishments.

Step 3: Printing the Jewelry

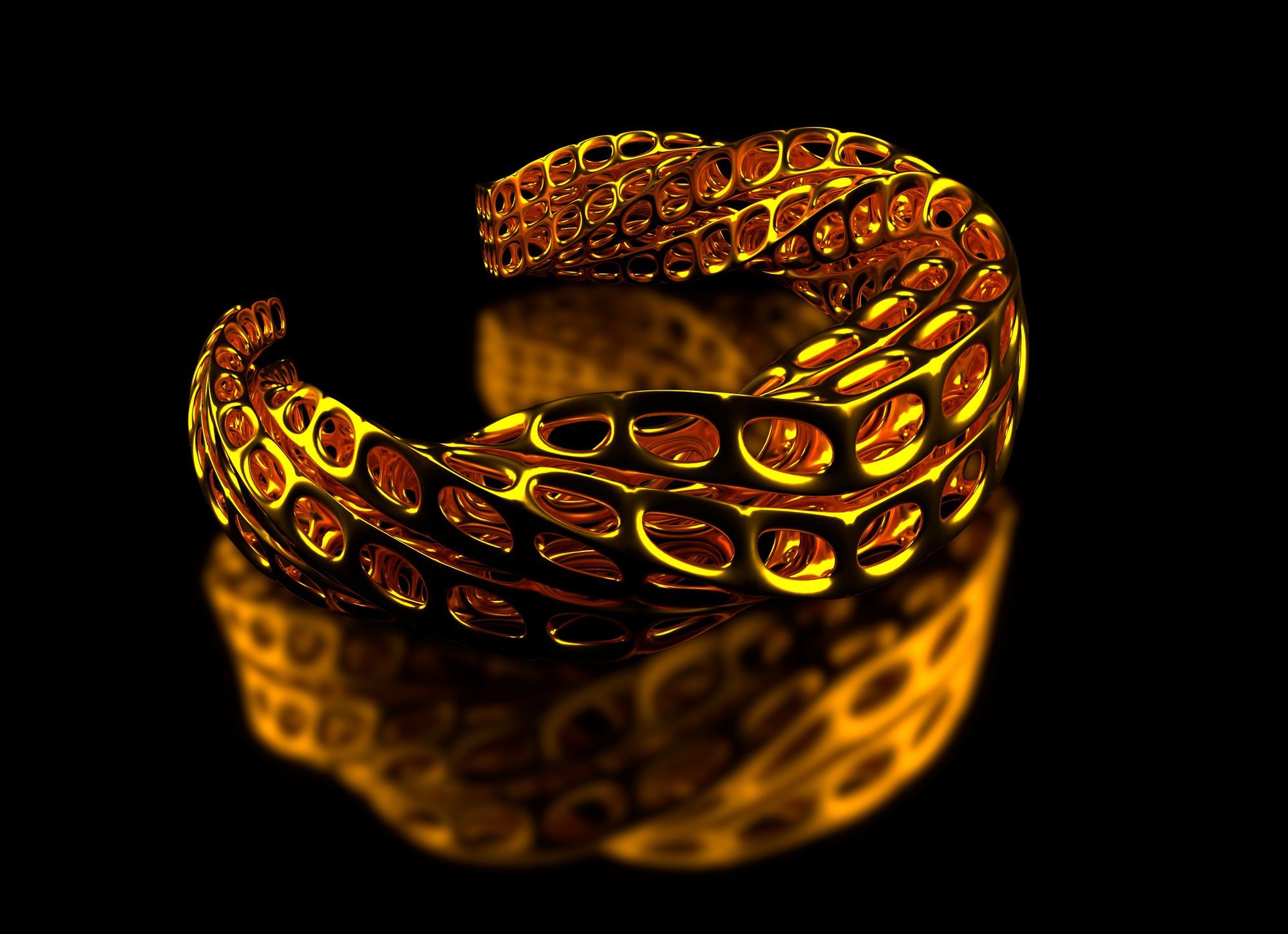

The next step is to print the jewelry using a 3D printer. This can be done using a variety of materials, such as metals, plastics, or even ceramics. The most common materials used for jewelry 3D printing are metals such as gold, silver, and titanium. However, other materials such as plastic, ceramics, and even resin can also be used. The type of material used will depend on the final design and the desired properties of the finished piece.

Step 4: Finishing and Polishing

After printing, the jewelry will need to be cleaned and finished. This may include polishing the surface, removing any excess material, and adding any additional details or embellishments. Depending on the material used, the finishing process may involve sanding, polishing, or even electroplating. The goal is to achieve a smooth and polished surface that is free of any defects or blemishes.

Step 5: Post-processing

The jewelry has to be cleaned and polished after printing, then it can be assembled and set with stones or other embellishments if needed. This step is crucial to give the final touch to the jewelry and make it look more professional and elegant. It's also the stage where the jewelry will be checked for its strength and stability to ensure that it's ready to be worn.

3D printing technologies that are commonly used for manufacturing jewelry:

1. Stereolithography (SLA):

This technology uses a laser to cure liquid resin into a solid object. SLA is known for producing high-resolution and detailed prints, making it a popular choice for creating intricate and complex jewelry designs. Know more

2. Selective Laser Sintering (SLS):

This technology uses a laser to sinter together powders of materials, including metals, plastics, and ceramics, to create a solid object. SLS is a cost-effective option for producing jewelry in large quantities and is commonly used for creating pieces in precious metals such as gold and silver.Know more

3. Direct Metal Laser Sintering (DMLS):

It's a process that uses a laser or an electron beam to melt and deposit metallic powders onto a substrate, building the object layer by layer. This technology is known for its high precision and high-quality prints, and it's the perfect fit for creating intricate and detailed jewelry designs. Know more

Key Design Considerations for jewelry 3D printing

File format compatibility: The jewelry design must be in a format that is compatible with the 3D printer being used. Commonly used formats include STL and OBJ.

Scale and size: The size and scale of the jewelry piece must be considered when designing it for 3D printing. The design should be optimized for the size of the printer's build volume.

Jewelry specific features: Features such as prongs, settings, and undercuts must be designed in a way that allows for proper support structures to be added during the printing process.

Materials: The type of material used for 3D printing will affect the final product, such as its strength, durability, and appearance. Popular materials for jewelry 3D printing include metals, wax, and resin.

Finishing: The jewelry piece will require post-processing finishing such as polishing, sanding and electroplating to give it a final shiny appearance.

Quality control: Quality control must be applied throughout the entire process to ensure that the final product meets the required standards and specifications.

Future of 3D printing in Jewellery Industries

3D printing technology has the potential to revolutionize the jewelry industry in a number of ways. One of the main benefits is the ability to quickly and easily create customized pieces. With 3D printing, jewelry designers can create one-of-a-kind pieces tailored to the exact specifications of individual customers, without the need for expensive and time-consuming traditional manufacturing processes.

Another advantage of 3D printing is the ability to create complex designs that would be difficult or impossible to produce using traditional methods. With 3D printing, designers can create intricate and detailed pieces with a level of precision that is not possible with traditional manufacturing techniques. This allows for greater creativity and artistic expression in the design of jewelry.

In addition to these benefits, 3D printing also offers cost savings for both the designer and the customer. Traditional manufacturing methods can be expensive, especially when producing one-of-a-kind pieces. With 3D printing, the cost of creating a single piece is significantly lower, making it more affordable for customers and more profitable for designers.

Furthermore, 3D printing technology also plays a vital role in sustainability. It reduces wastage and also enables the use of more eco-friendly materials like bio-plastics, and recycled metals.

Finally, 3D printing technology has the potential to open up new markets for the jewelry industry, particularly in the online space. With the ability to create customized pieces quickly and easily, designers and manufacturers can reach a global audience with their designs, and customers can purchase unique pieces from anywhere in the world.

Overall, 3D printing technology has the potential to greatly enhance the jewelry industry by offering new opportunities for customization, creativity, and cost savings. As the technology continues to evolve, we can expect to see even more exciting developments in the field of jewelry design and manufacturing.