Problem Statement

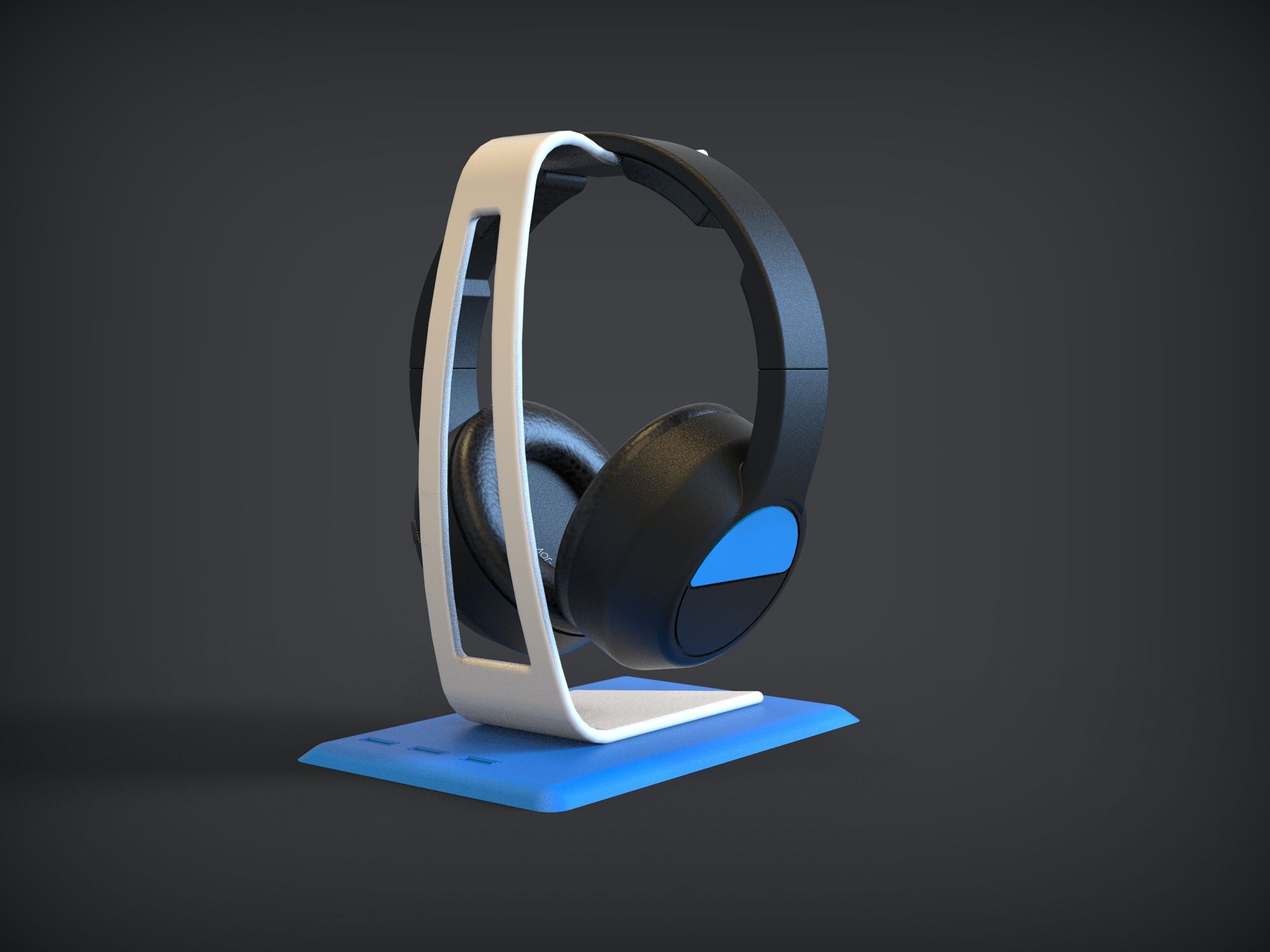

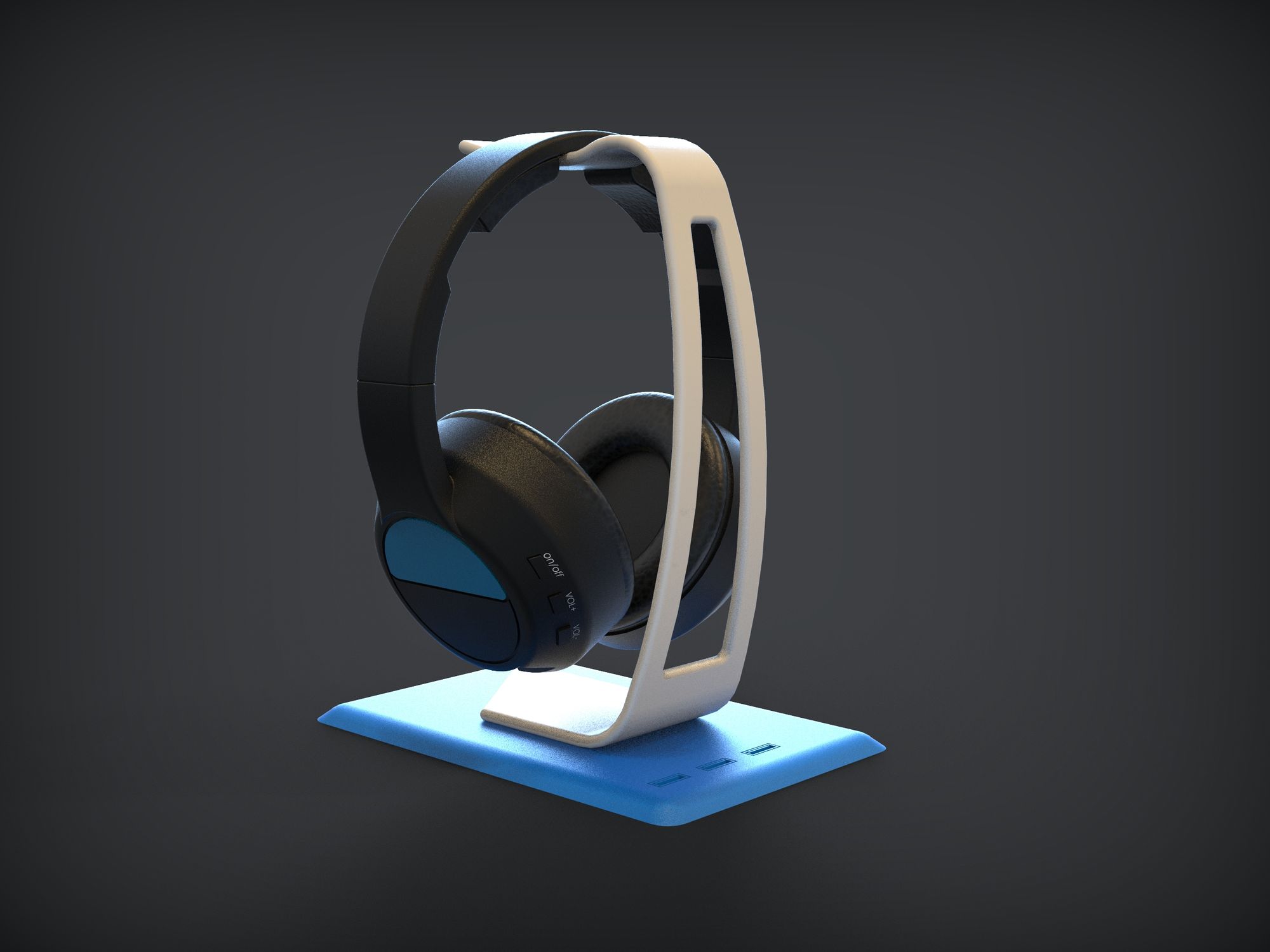

To design a wireless headphone and its stand by considering the headphone design provided by the customer and considering additive manufacturing as the primary method of production.

Requirement Gathering

After discussing with the customer ,it was clear that they were looking for a wireless headphone with a stand.

We need to know the features what the customer is looking for to continue with the design.

Below-listed are the requirements gathered from the customer by our technical sales team.

- They are looking for a simple and compact design.

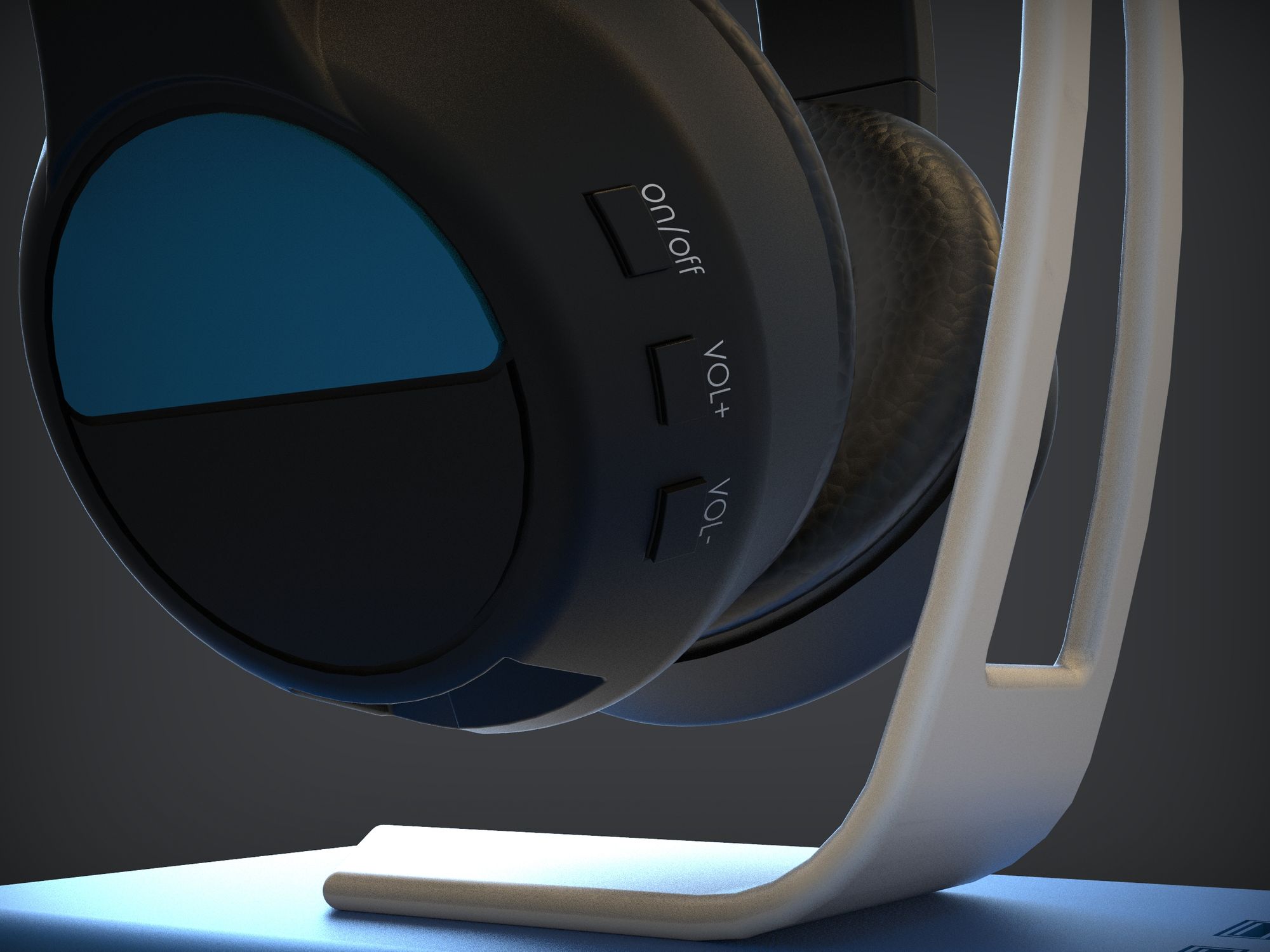

- Need sliding mechanism for expanding the headphone.

- Stand should have magnetic charger.

- stand needs to have a good aesthetic look.

- The locking mechanism for the housings of components should be simple and strong.

- The PCB image and dimension will be provided.

- The housing should withstand the heat produced by PCB.

- Headphone should have aux jack and charging port(to connect with the stand).

- Customer is looking for 3d printing all parts of headphone.

Once we get all these requirements the design team will be able to decide the timeline of this product development.Usually this phase takes one to two hours depending on the complexity of the design.

Market Research

This stage usually depends on the customers requirement.The product is looking for low volume production with very low cost method our team have gone through different manufacturing process to make this in low volume,we found some solutions like:

- FDM 3d printing

- SLA 3d printing

- SLS 3d printing

- silicon molding

- Injection molding using 3d printed molds.

For this phase our technical team took about 1 hour to shortlist these.Usually this phase takes 30mins to 8 hours depending on the complexity of the product.

Feasibility Study

Among the shortlisted method customer agreed to continue the design with SLA 3d printing method.

- 3d printing:as we are not looking for mass manufacturing this is a good option as it is feasible and can manufacture rapid prototype.

- Silicon molding: Mold making cost is more and the lead time is higher.

- Injection molding using 3d printed molds: this product is not feasible if we are manufacturing only a single peace.

Our team had done the feasibility study on this ,and we concluded that by SLA additive method we could process very detailed product as this product is complex.We cannot continue with other 3d printing methods as they won't be able to produce a complex product like this.

For this phase our team took only 1 hour to come with this conclusion.

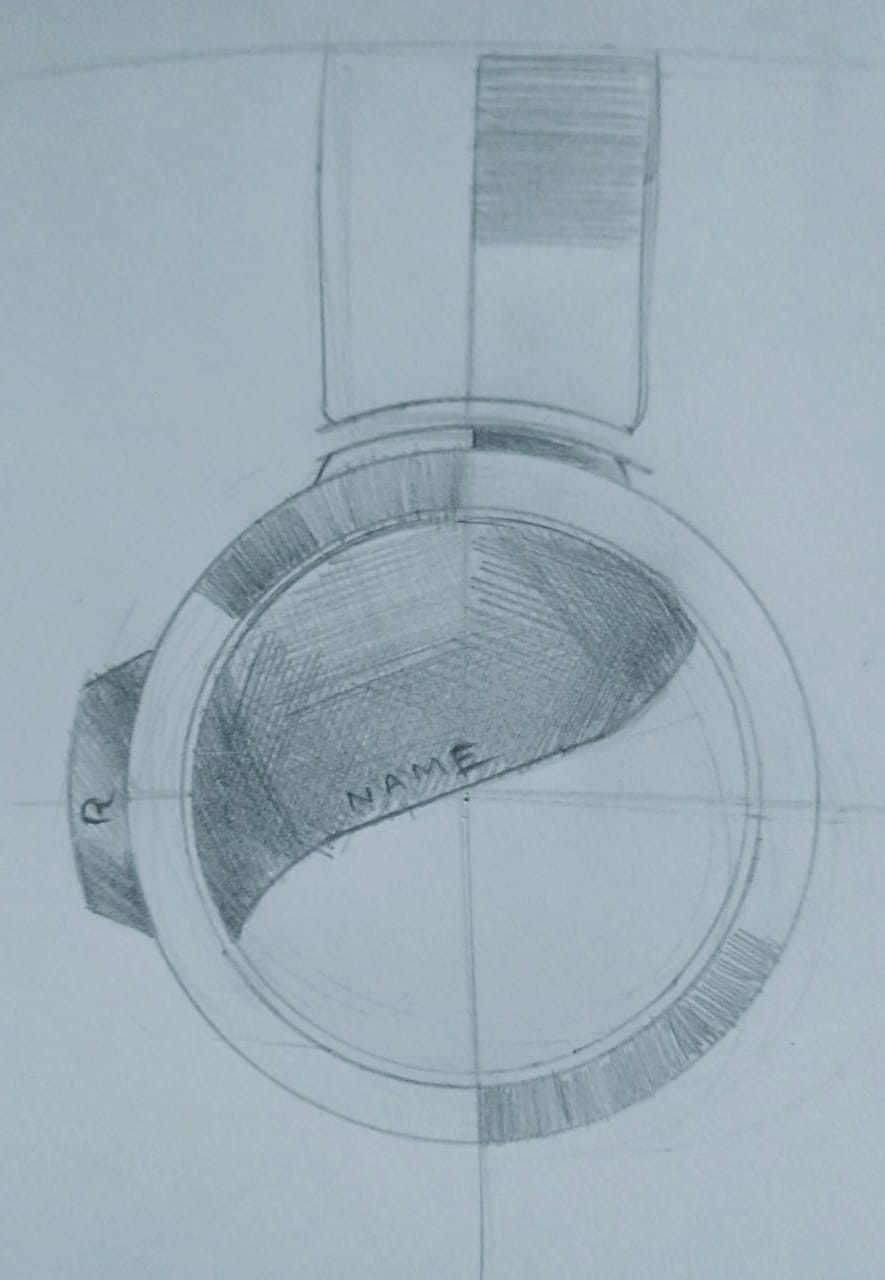

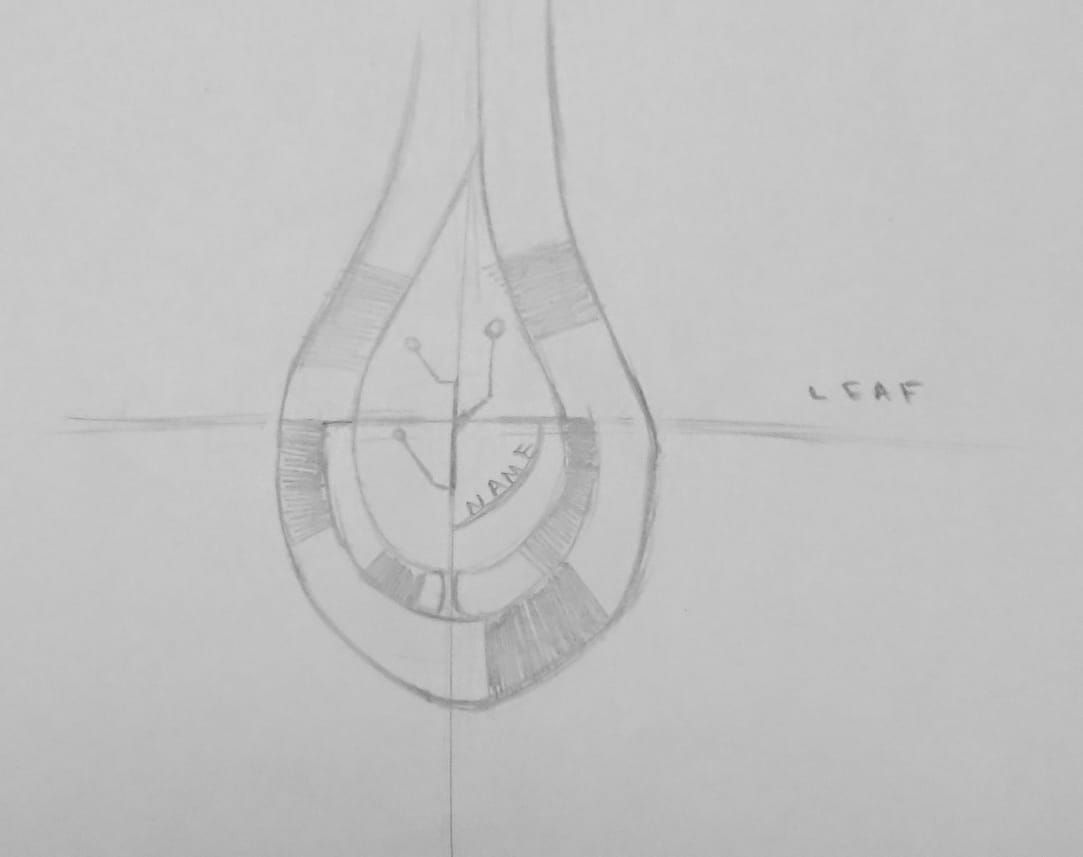

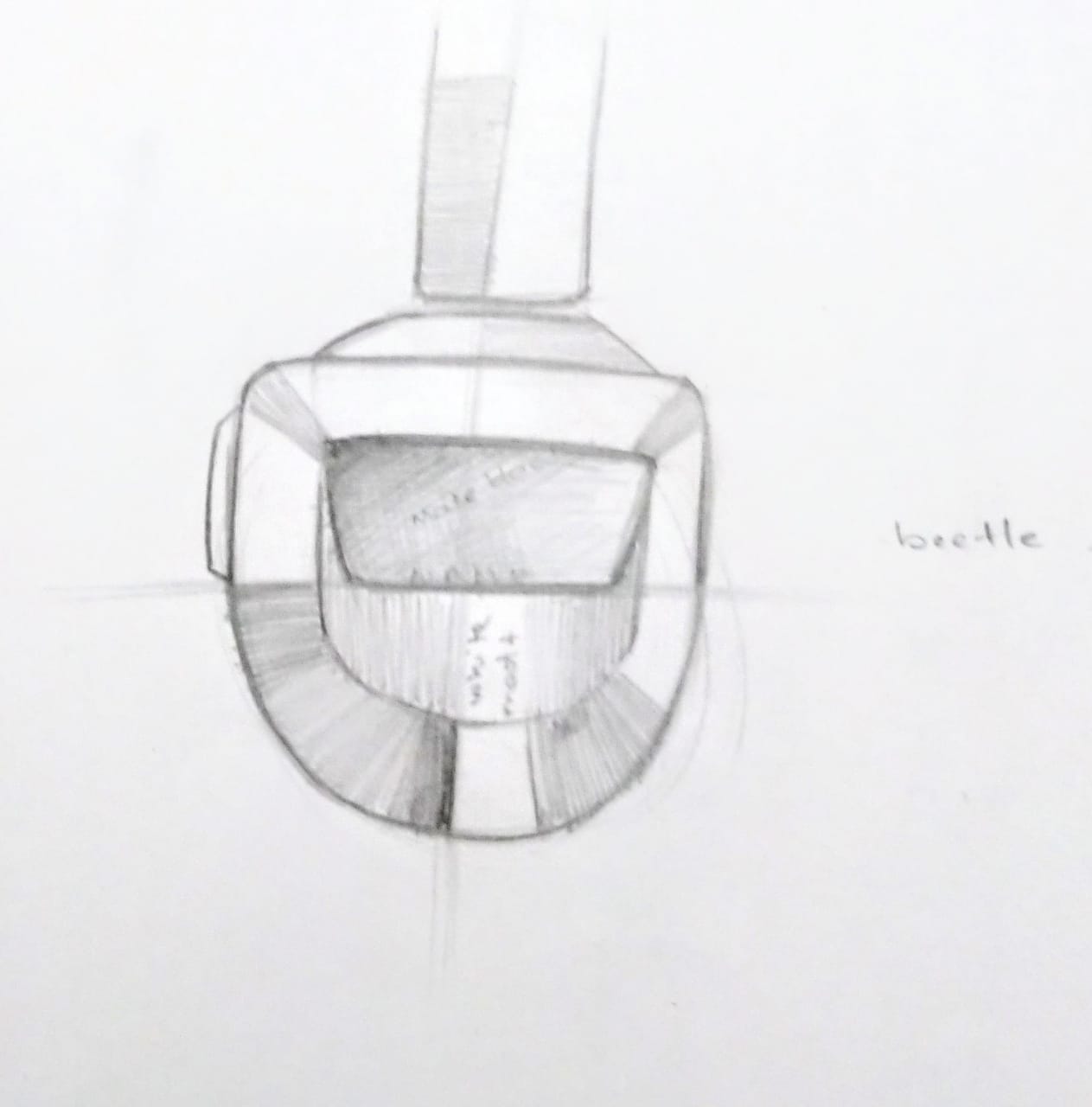

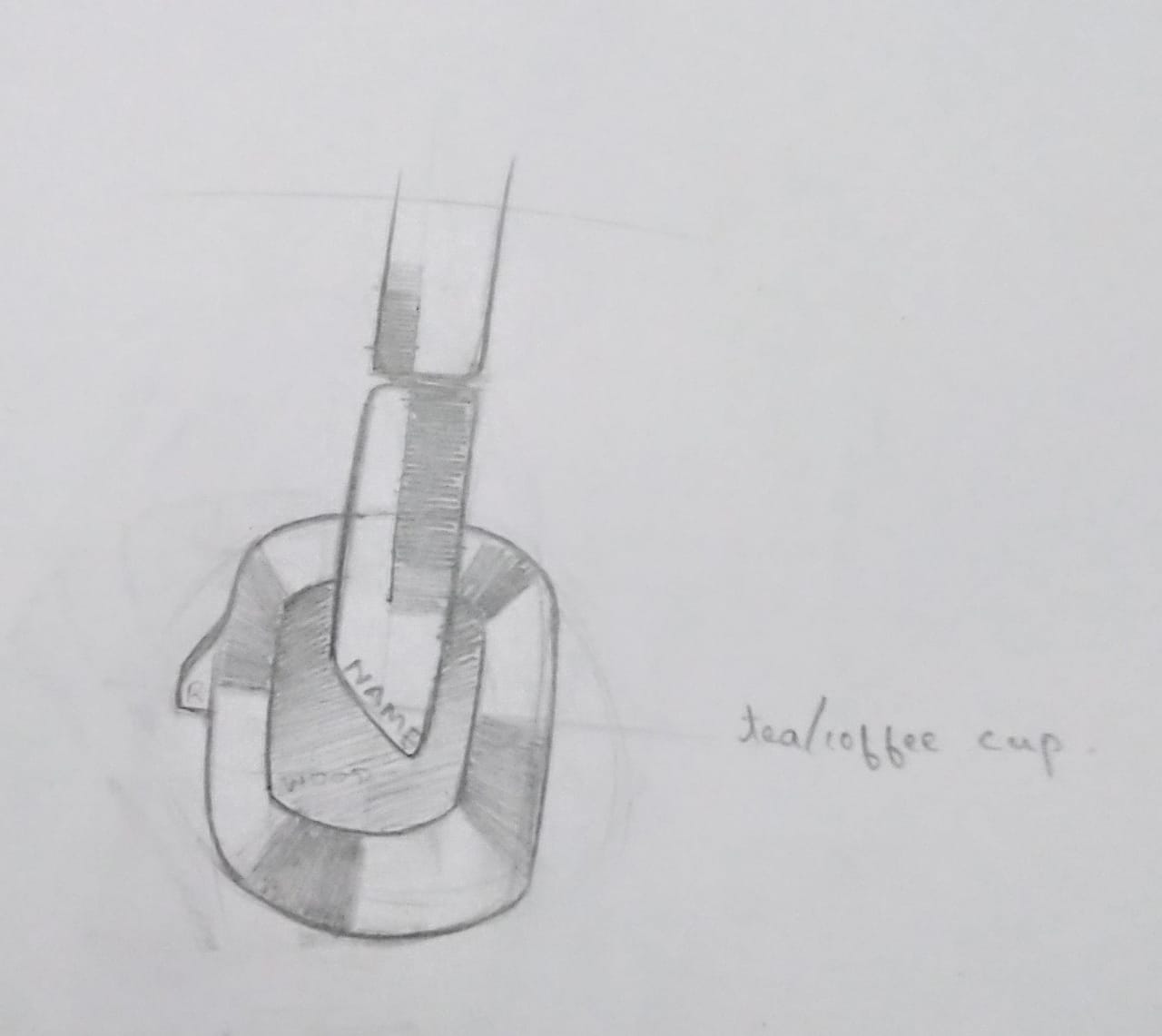

Concept Design

once we have confirmed the manufacture method and feasibility, our team started with conceptual design.

This stage is very important as we have to take in consideration of the aesthetic look,component placement and feasibility of the design.

We have gone through many design ideas to give the product better aesthetic look.

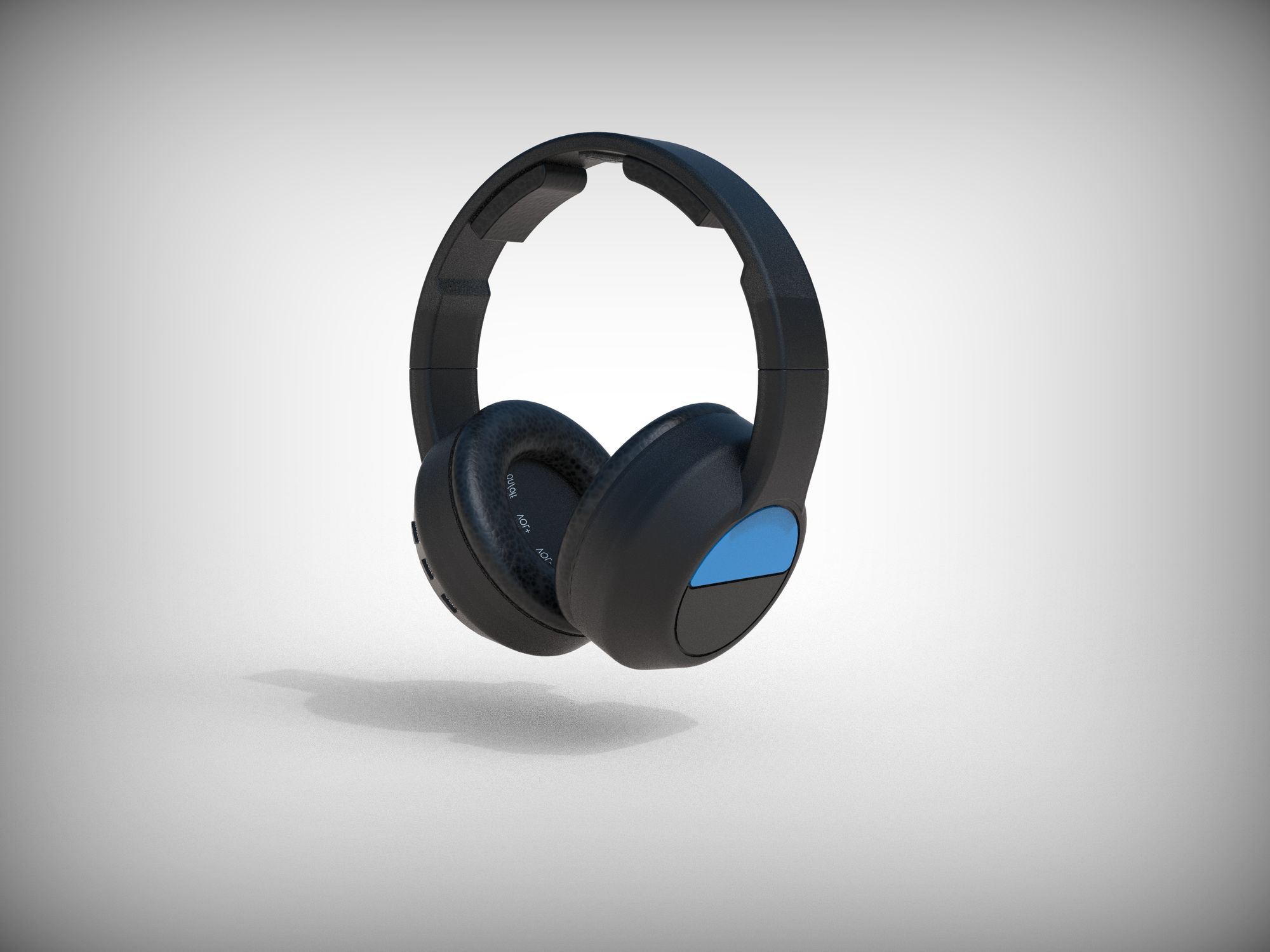

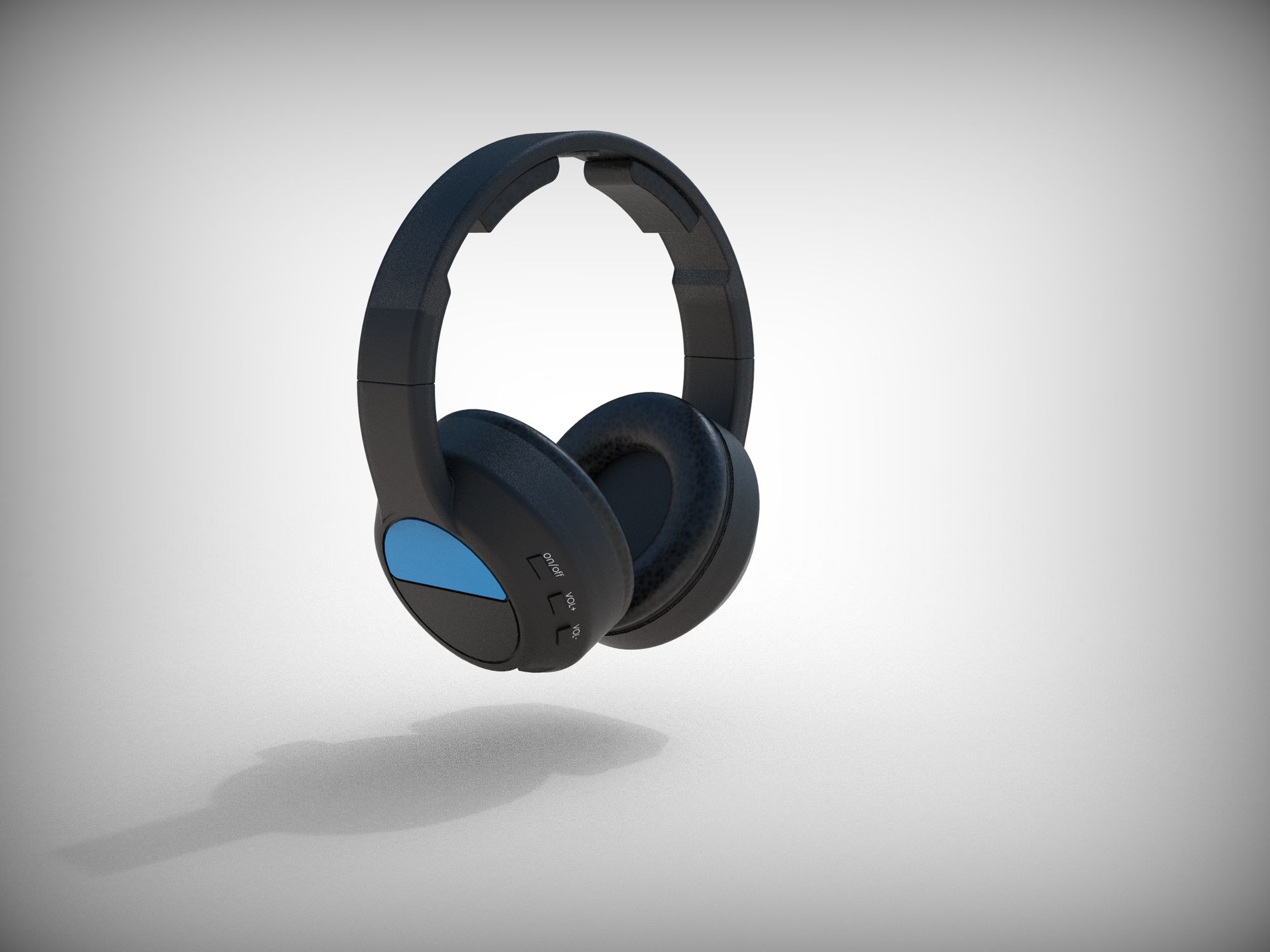

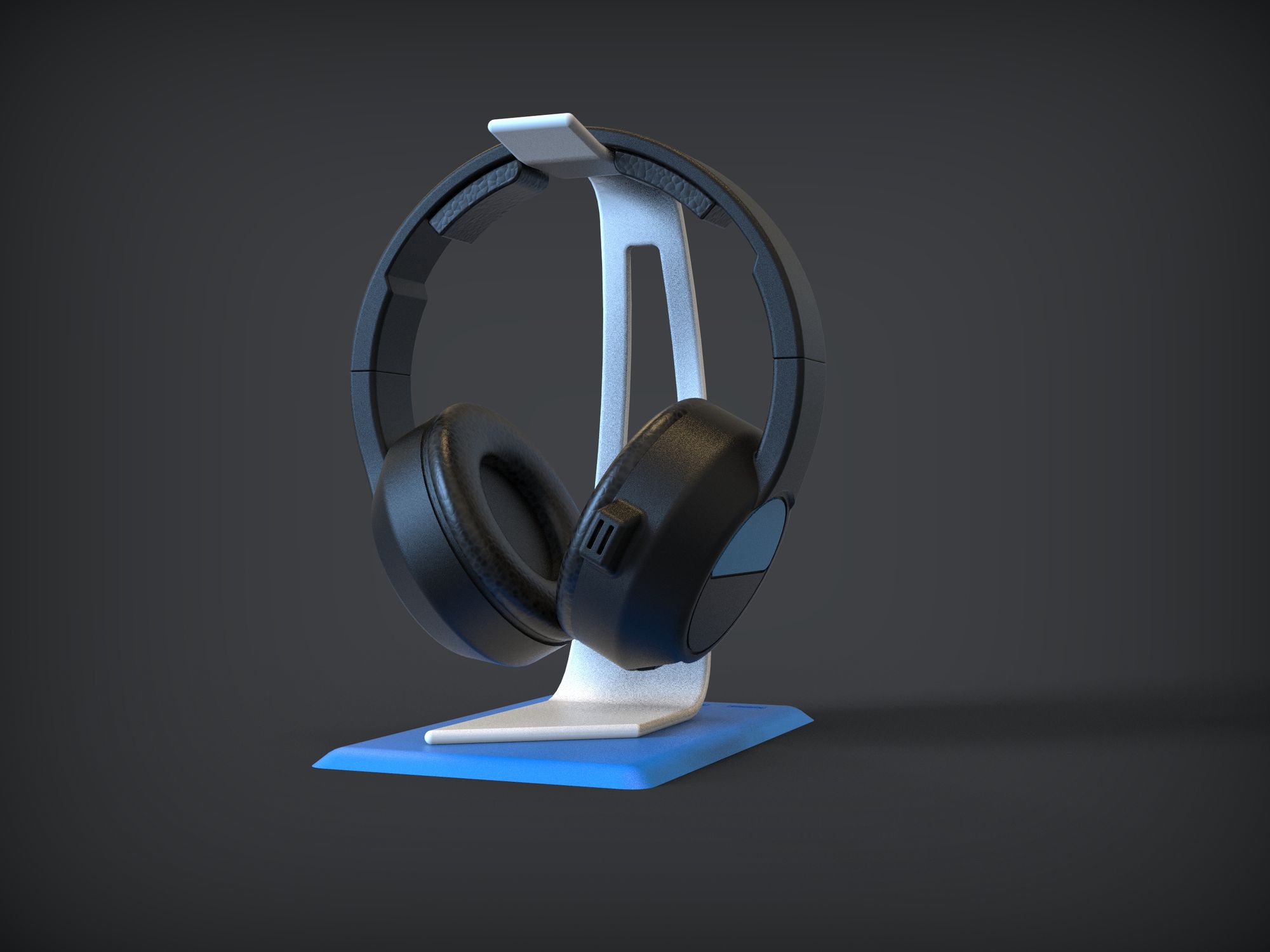

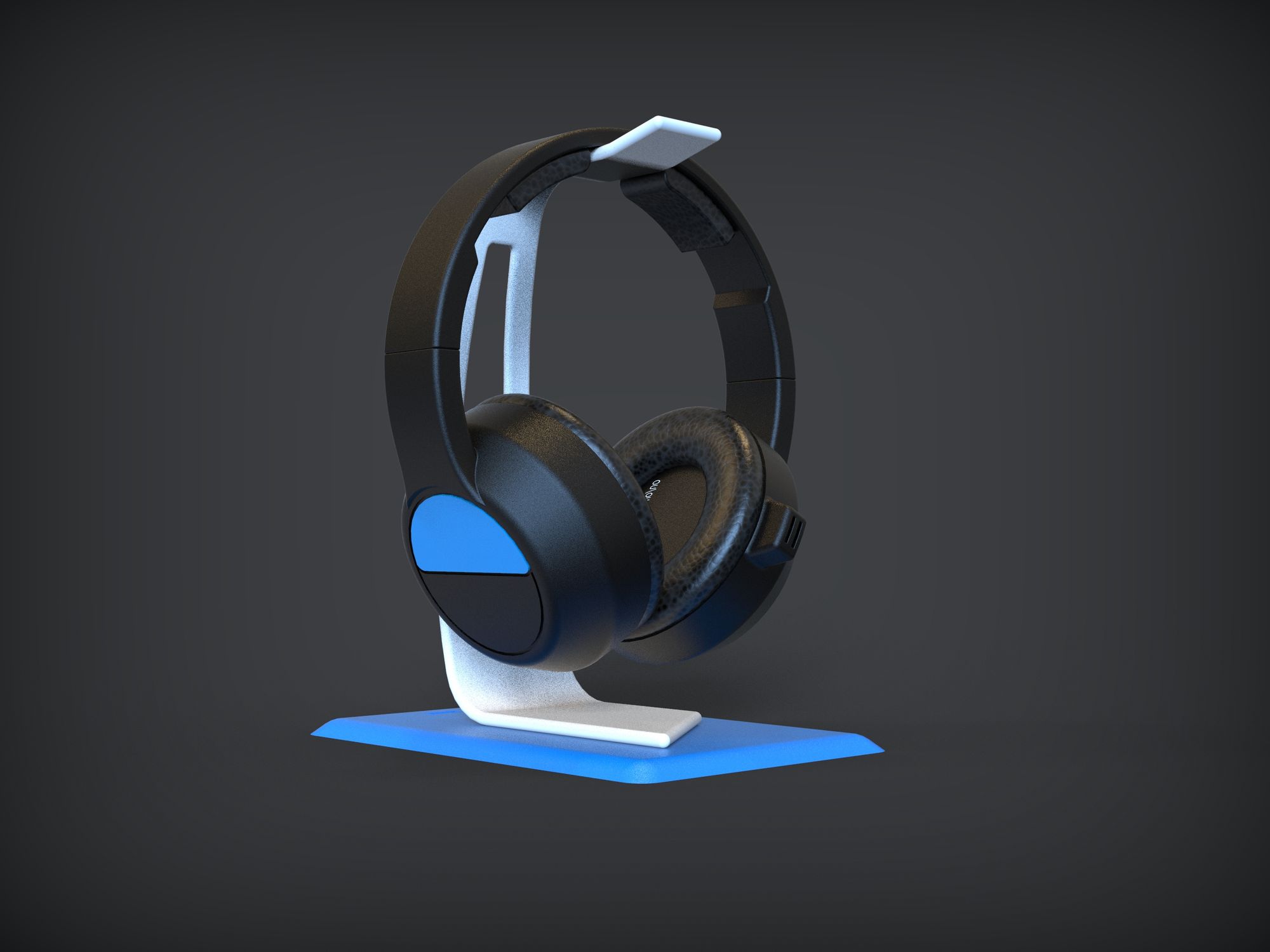

We sketched 4 product designs by taking these considerations.Then our design team made a rough CAD model (which took about 2 hours)and took screen shots to give customer preview images.

This phase takes 2 to 8 hours(or more)depending on the complexity of the design.our design team took only 3 hours.

Mood board

Feedback from the customer

After sending the images they have selected one design, our design team and customer will have a meeting to confirm the design and proceed to the next stage.

In our design when we had the meeting the customer told to give a better aesthetic look to the headphone stand and the magnetic charger should not irritate the head.

We gave one suggestion to give extra spacing for the mic which will give more aesthetic look to the design,customer agreed with that.

This phase completely depends on the the customer.The time taken will be very less like the meeting will be as quick as 1 hour.

Initial Prototype Design

After all the above discussions we can start making the main CAD file of the product.The finalized requirements are :

- Technology : SLA 3d printing

- Expanding mechanism of headphone : sliding mechanism

- Housing interlocking mechanism : snap-fit mechanism

In the CAD modeling, the challenging part was the mechanism to expand the headphone.Our design team, after 2 revisions, got the precise dimensional values for the mechanism,in which it will slide through easily.In the interlocking mechanism we got the precise dimensional result in the first go itself.Another challenging part was ,whether we should screw the housing or glue to the inside part of the headphone.After a meeting with the customer we concluded to use glue method to fit housings to the inside part of headphone.The wall thickness should be in the range of 1 mm to 2mm.After considering strength and feasibility we concluded to go with 1.2mm.

This phase took about 8 hours to model in CAD software.

Manufacturing and firm and fitment testing

After approval of the initial prototype we will start 3d printing using SLA 3d printed as we have already discussed.

After the printing is complete we tested the parts for any mistakes in the design.We also checked the snap fit mechanism and the sliding mechanism to check the strength and durability.

This phase takes minutes to days depending on the complexity of the product.

Feedback from the customer

After completing the printing all parts of headphone, we sent some preview images to the customer.We had a meeting with the customer and the customer gave a very good response.If there were any changes we have to change them.But in our case all were good.

This phase depends on the customer.For us it took only 1 hour.

Further optimization and Final design based on customer feedback

As per the request we had already sent the CAD file and got the feedbacks from the customer.After the approval of the product,we went on to manufacturing the parts.If the customer still give some changes, these changes will be chargeable.As we have to rework on which were not previously told by the customer.

For our design there was no changes and the customer was satisfied with the product.

submission of deliverables

After finishing all the process customer opted the option to receive the CAD file of the product in STEP format.

We have delivered the Headphone and headphone stand along with the CAD files to the customer(prototyping cost will be billed to the customer).

Total time that took for the whole process was 40 hours.